SRM Engineering offers a quality, professional engine reconditioning service.

- Needle roller bearing conversion

- Crankshaft grinding

- Dynamic crankshaft balancing

- Rebores

- Helicoils & thread repairs

- Lead-free valve seats

- Colisbro valve guides

- Gas following

- Fin repairs

- Alloy polishing

- Stove enamel for cylinders

NEEDLE ROLLER BEARING CONVERSION

BSA was aware of the shortcomings of the crankshaft bush and developed their crankshaft oil feed system for use with their racing engines. Our Needle roller and oil end feed conversion eliminates the problems associated with the timing side bush. The bush is replaced by a combined ball and needle roller bearing, which withstands substantial radial and axial load. The combined bearing eliminates end float; locks the crankshaft to the timing side, resulting in no more shimming of the crankshaft. The oil ways are altered and re-routed so the oil is fed directly from the oil pump to the big ends (via an oil seal housed in the timing casings) and through an end feed quill situated at the end of the crankshaft.

CRANKSHAFTS

All our crankshafts are reground accurately to the correct specification radii. The sludge trap is cleaned out to remove any foreign particles which may interfere with the grinding process. Then the crankshaft journals are reground to size. The crank is then cleaned once more before reassembling the sludge trap. The main journals are then highly polished to the correct surface finish. We also carry out repairs to worn splines and also reclaim worn shafts. We recommend our customers have their dynamical crankshaft balanced as part of their engine rebuilds. This helps reduce the vibration of the vertical twin engine. In contrast to the static balance, the dynamic balance addresses not only the circumferential balance but also the balance across the shaft (rocking couple). Dynamic balancing will produce the smoothest ride.

CYLINDER HEADS

We can provide all the services and parts required to recondition your cylinder head. Only the exhaust valve seats have to be replaced to run your classic four-stroke engine on lead-free petrol . This is due to the intense heat produced around the exhaust valve seat area.

We replace the seats with a special hardened steel insert, we can supply compatible valves for the replacement seats. Lastly, we can fit the Valve seats to any cast iron and aluminium cylinder head. We use a Colsibro material for the valve guides: Copper, Nickel, and Silicone alloy resists wear, corrosion and can cope with rapid temperature changes. It allows closer tolerances to be used which produces a cleaner running engine.

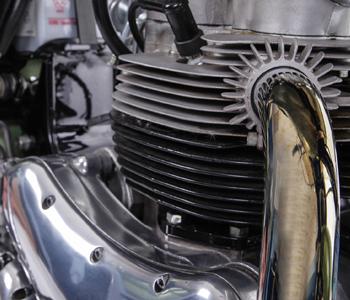

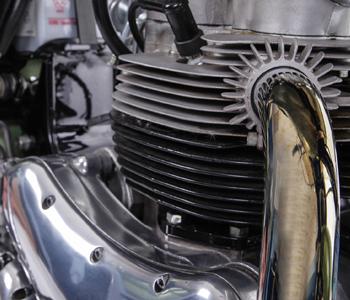

CYLINDERS

All our cylinders are bored to within 0.002” (thou), then honed to an exact size, within two tenths of a thou (0.0002”) tolerance to produce the ideal surface finish to "bed in" the piston rings.

BEARINGS AND BUSHES

All the bearings and bushes that are fitted are of the best quality – we guarantee the engines that we rebuild and have to be sure all the components are to the highest standard.

HOW TO START THE REBUILD

If you are sending a complete engine, you will need to build the engine into a substantial wooden box.

We offer a complete service in which we will remove the engine, do a complete rebuild and refit the engine back to the chassis. We would then put the bike on the rolling road and set up the ignition timing and carburation.