MAGNETO

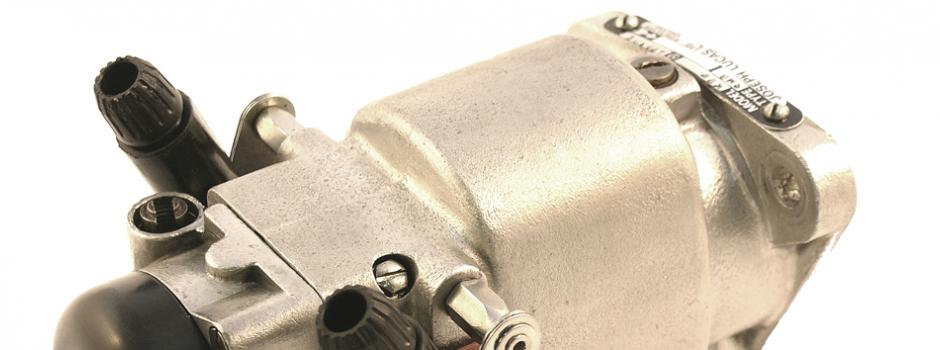

We specialise in the renovation of the LUCAS K2F and K2FC magneto as fitted to NORTON twins.

The most common problem with original magnetos is failure once hot. The engine will start from cold

Then run for a short while, a misfire will develop and the engine will finally stop. Once the engine is cold again the engine will start. This is usually due to a breakdown in the insulation of the condenser or of the armature windings themselves.

When we undertake renovation of these magnetos we examine the following:-

• Mechanical - Bearings, insulation, washers and shimming the armature

• Electrical - Armature windings, Condenser, Slip ring, Points and Bushes

• Magnetic - Check magnetism and Re-magnetise magneto body

• Ignition - Check Spark strength, Spark timing and stability

We use the CRYPTON MAGMASTER (from the 1950s) to do a comprehensive testing programme on each magneto we rebuild. This allows us to do slight adjustments to the magneto to achieve the best constant and accurately timed spark that the magneto is able to produce.

The final 20 minute hot running test programme includes:-

• Checking the normal spark HT Voltage;

• Checking the maximum available spark HT Voltage;

• Checking the ignition timing stability over rev range;

• Checking the ignition timing for correct timing angle (for most twins this is 180 degrees);

By performing this test programme we can be confident that the magneto you fit to your engine will be at peak performance and will remain reliable for years to come

Send your magneto to us, we will test it to ascertain its’ faults, provide an estimate and contact you to discuss the work required.

Each Renovated magneto is backed by our 2 year guarantee.

Have you considered replacing the magneto with an electronic ignition?

SRM ELECTRONIC MAGNETO CONVERSION KITS

DYNAMO

At SRM we specialise in the renovation of these particular models of LUCAS dynamos.

In the 1940s the LUCAS E3H (40 Watt) unit was used extensively on a variety of British single cylinder engines later to be replaced by the more powerful LUCAS E3L (60 Watt).

The E3L dynamo was used on many British twins such as the early NORTON twins.

The design of this dynamo is the same throughout the range but different drive shafts are used for different models.

Each dynamo is tested on the CRYPTON ELECTRICAL TEST BENCH to determine its condition and an estimate of the cost to renovate the unit is produced.

If the dynamo was to be fully restored a new armature and field coil would be fitted together with new bearings. The outer body would be Nickel plated and the alloy ends bead blasted. New brushes would be fitted and then the dynamo would be thoroughly tested.

Firstly the dynamo is wired for a ‘motor’ test - this runs the dynamo as a motor, the motoring speed is checked as is the polarity and rotation. This test also polarises the magnetic field in the field coil core;

The dynamo is then fitted to the CRYPTON ELECTRICALTEST BENCH to be driven as if the dynamo were fitted to the engine. This test confirms the dynamo will charge when fitted to the engine and in the correct polarity for the earthing system on the bike.

Each Renovated dynamo is backed by a 2 year guarantee.

ALTERNATOR MODELS

We can advise on various upgrade for the alternator models and improvements for the charging system.