Engineering services

- Cylinder Rebores

- Cylinder head reconditioning

- Dynamic crankshaft balancing

- Welding and fin repairs

- Blasting & Polishing

With fully trained and experienced staff, we can undertake many engineering jobs to not only BSA, Triumph and Norton models but also to other makes and models.

CRANKSHAFT

Sludge tap thoroughly cleaned.

Re-grinding accurately to size and specified radii.

Dynamic balancing to smooth out the vibrations.

CONRODS

Checked and polished.

Standard Small ends re-bushed or special oversize made.

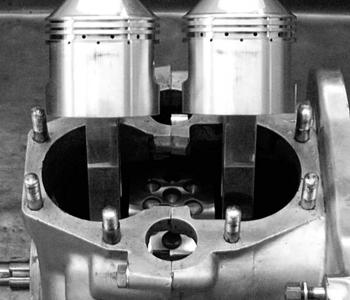

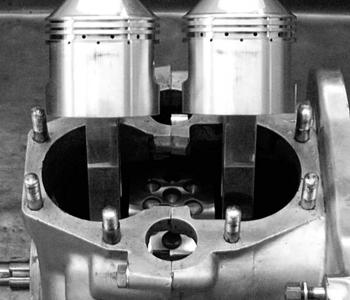

CYLINDER HEAD

Colsibro valve guide fitted and sized Valve seats cut.

Hardened valve seats fitted to run on Unleaded fuel.

Repairing Fins and thread repairs.

Blasting and cleaning to restore the Original finish.

Gas flowing and tuning.

CYLINDER BARREL

Bored to within 0.002” (thou) then honed to an exact size, within two tenths of a thou (0.0002”) tolerance,

Bore size is matched to piston dimensions for correct clearance.

Bores are straight and parallel.

Barrels are shot blasted and a high-quality stove enamel paint before machining.

BUSHES, BEARINGS & OIL SEALS

High-quality bushes are always used and can be made to size to accommodate worn shafts or casings.

New quality bearings and oil seals are always fitted.

WELDING REPAIRS

Specialist welding, especially on alloy casings.

Welding and re-machining holes.